Undoubtedly one of the fastest growing sectors of the gas and oil arena is energy providers. An energy service company (ESCO) is a business that boasts a wide range of energy services including designs and implementation of energy savings jobs, retrofitting, energy conservation, energy infrastructure freelancing, power generation and energy sources, and risk assessment. The ideal objective of every ESCO is always to deliver noticeable savings in energy costs by providing energy audits and assessments and effectively making processes much more efficient in regards to energy rates.

Based on past stories and headlines out of energy media websites, going to 2022 we are set to see historic high big oil prices. The concern being though is the fact that there are numerous governments with their unique agenda that conflicts with progression in the oil centered energy industry. In Canada albeit there are a handful of provinces and regions with oil reserves, none have more than that of Alberta. The province has 39% of Canada’s remaining oil reserves.

It has become very clear that the new normal post COVID19 is forcing firms to examine their business models and adapt consequently. Technology has a considerable function in the energy market and as such ESCOs have adapted to service this now technologically progressed vertical.

It has become very clear that the new normal post COVID19 is forcing firms to examine their business models and adapt consequently. Technology has a considerable function in the energy market and as such ESCOs have adapted to service this now technologically progressed vertical.

It is fairly unknown outside of the sector however energy prices and efficiency can be refined and for that matter that is the primary mission for most energy service company. Deregulation of the energy sector in the 1990’s was the catalyst that propelled the surge of energy service firms. Now they are customary within many organizations which include municipalities, school districts, industrial jobs and commercial markets.

In 2006 the trade group NAESCO stated energy service firms increased by 22% and stated $2.6 billion in revenue marking a paramount moment for ESCOs through the country. In Canada the popularity of energy service companies also grew significantly mostly in the oil abundant province of Alberta.

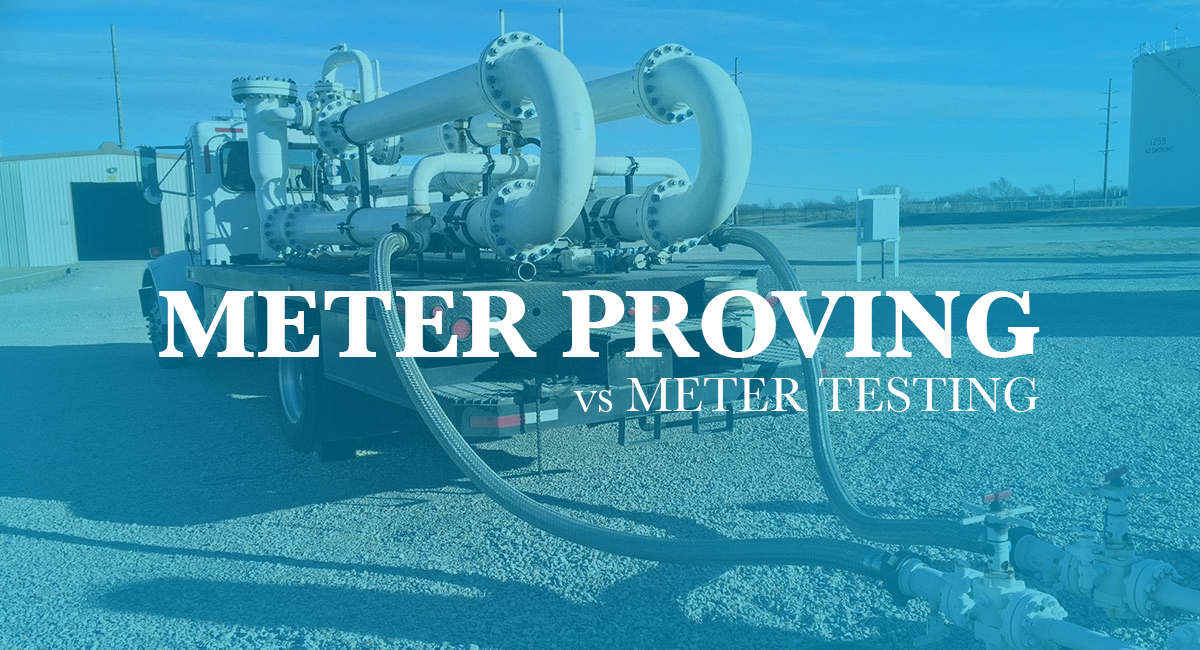

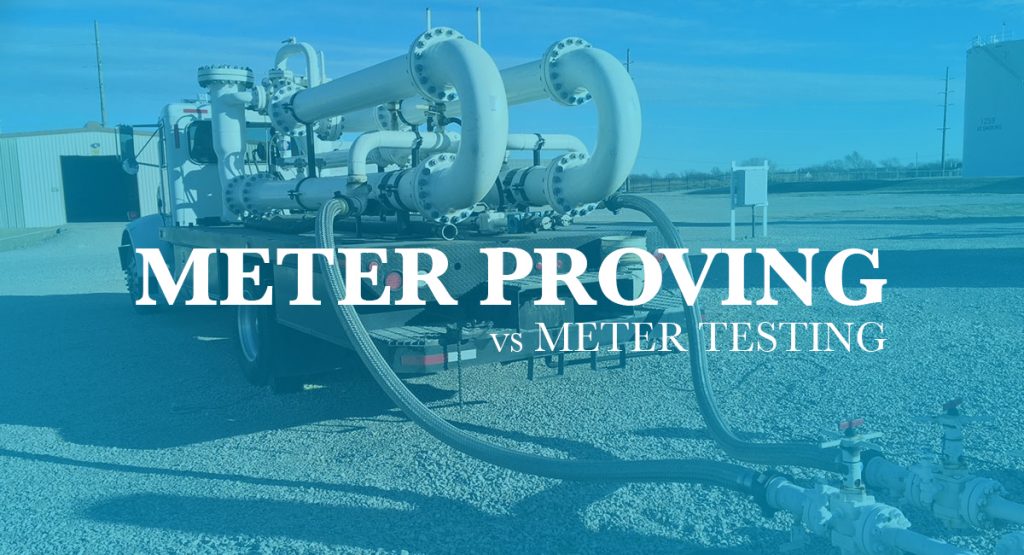

There are a large number of types of energy service organizations which include but not limited to: meter testing and proving, industrial mobile boilers, fuel flare venting, sampling and analysis, shutdowns and turnarounds, industrial cleaning and plenty of other energy providers. But why bore (no pun intended) you with the particulars of all of them.

Energy procurement providers also play a vital role in the management of energy costs with the milestone of decreasing expenses and making efficiency a top priority in most organizations. The central focus of energy consultants should be to save their customer dough by negotiating energy prices and making current operations more energy-efficient. Setting a baseline before starting on any energy cost savings effort is a key factor to any energy management service. Energy consultants use a defined start task which should be to perform a wholesale and thorough energy audit to be later applied as a measurement of future energy cost savings. Commonly you will find the energy consultancy firm operating jointly with managers inside any organization they’re contracted by. This permits for brisk decisive decisions. It really is important to grasp the importance of immediate access to decision makers when reporting on energy finances and in particular when negotiating prices.

Field energy service providers firms offer a wide array of solutions this includes meter proving, sampling and analysis, electrical and instrumentation, vegetation management, automation and controls and even software solutions. Overall though we’re on the cusp of a paradigm shift within this sector due largely in part to the pandemic that has gripped the world over the past 6 months.

We spoke with Branden Bodah, an operations executive with Barton Energy providers and here’s what he had to say.

“The energy vertical has seen many hits over time and if I’m to be truthful, though this pathogen is damaging and in a wholesale way, the sector will bounce back. Our corporation as an example has used the past couple months to strategize on how we wish to go forward in 2021.”

Turnaround services is one more aspect to the assortment of service providers by energy service professionals which entails project management during the course of operational shutdowns of factories at the time of maintenance. This kind of service can entail numerous other service providers within it including mobile boiler rentals, measurement, meter testing and others. Based on the scale of the project, these contracts in most cases last from two to four weeks.

Market guidelines and government and industry regulations are the primary backbone to which all energy service organizations must function. Not all energy service organizations are the same however they do share similar goals one among them being decreasing energy spending.

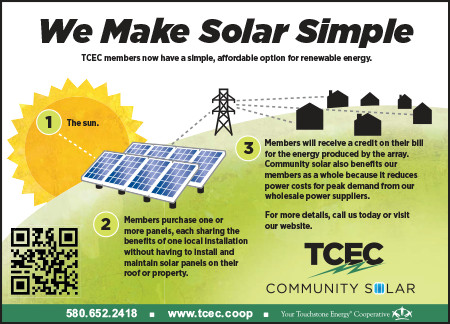

Ahead of COVID-19 we had already begun to see utility firms begin to reinvent themselves and make themselves more pertinent by bundling services you might not of previous thought they could offer. Things like internet providers now offering bundles with TV and home phone on top of the internet service. In Canada we commonly see energy providers partnering with government so they’ll be able to further broaden their scope with customers this includes the prominent gas company in Canada named Enbridge, Enbridge has worked diligently to extend their providers and products to capture more of the energy consumer sector. This phenomena was the inception of the current energy provider reinventing itself as a twin pack offer both the solutions like a utility company and the energy itself.

You’re probably asking yourself that if this truly is transpiring then wouldn’t that make private energy services companies obsolete? If there is any takeaway from reading this is that energy solutions companies are going to be with us for the foreseeable future and adapting to whatever the world brings its way.

It has become very clear that the new normal post COVID19 is forcing firms to examine their business models and adapt consequently. Technology has a considerable function in the energy market and as such ESCOs have adapted to service this now technologically progressed vertical.

It has become very clear that the new normal post COVID19 is forcing firms to examine their business models and adapt consequently. Technology has a considerable function in the energy market and as such ESCOs have adapted to service this now technologically progressed vertical. Despite the fact that meter testing has been around for over 100 years the equivalent standard is present nowadays as it did all those years ago. This is why testing via this method is sensitive to numerous different variations and insecurities.

Despite the fact that meter testing has been around for over 100 years the equivalent standard is present nowadays as it did all those years ago. This is why testing via this method is sensitive to numerous different variations and insecurities.

Follow Us